A Biased View of American Plastics

Wiki Article

Indicators on American Plastics You Need To Know

Table of ContentsAmerican Plastics Things To Know Before You Get ThisThe 7-Second Trick For American PlasticsGetting The American Plastics To WorkIndicators on American Plastics You Should KnowFacts About American Plastics UncoveredThe Single Strategy To Use For American Plastics

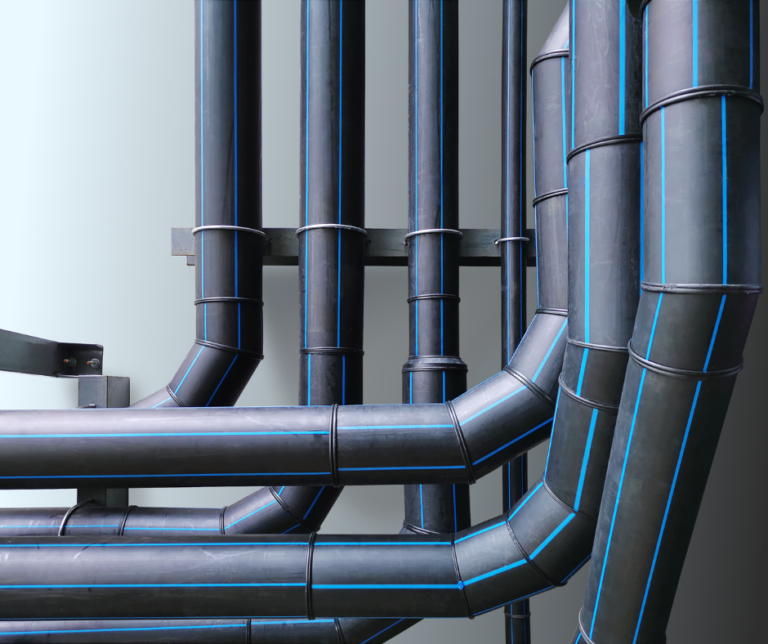

This might include securing pipelines from severe temperatures, staying clear of direct exposure to chemicals or corrosive materials, and implementing appropriate assistance and anchoring to stop drooping or activity. Right here are response to some often asked questions pertaining to HDPE pipeline PSI scores: The maximum PSI ranking for HDPE pipelines can vary relying on factors such as size, wall density, and material make-up.No, it is not recommended to utilize a lower PSI-rated HDPE pipe for a higher-pressure application. Doing so may lead to pipe failure, leakages, or other safety threats.

You can validate the PSI score of an HDPE pipeline by inspecting the maker's documents and certification. Trustworthy suppliers offer precise and trustworthy details about the PSI rating of their pipelines. The HDPE pipe market is continuously developing, with recurring improvements in modern technology and manufacturing strategies. New material make-ups are being created to improve the stamina, sturdiness, and performance of HDPE pipelines.

The Best Guide To American Plastics

Remain informed concerning the most current advancements in the industry to leverage the improvements that can additionally enhance your projects. With this comprehensive guide available, you are well-equipped to make informed decisions and achieve successful results. The Great Pyramid of Giza The Hanging Gardens of Babylon No matches were found.However, all local water supply involve streaming water. For instance, HDPE (PE4710) DR 17 pipe has a fixed pressure rating for water of 125 psig. The working pressure rating (WPR) is based on real system needs and is a, that is, a pressure ranking for pipe with moving water.

At an everyday recurring standard flow rise velocity of 5 fps and at 80oF, the working pressure rating of HDPE (PE4710) DR 17 pipeline is also125 psig; similarly, the functioning stress score for PVC DR 18 is 120 psig per AWWA C900-07, Equation 4. As such, PE 4710 has a higher working pressure score than PVC at these typical problems.

Rumored Buzz on American Plastics

This associates to savings in replacement prices for generations to come. Yes, HDPE pipe, due to its density being somewhat much less than water, will float also when packed with water. When it is wanted to make certain flotation protection of the line, different kinds of collars, saddles, and strap-on flotation devices are available.Refer to Chapter 10 of the PPI Handbook of Polyethylene Pipe, 2nd ed. HDPE pipe's normal operating temperature variety is from -40 oF (-400 C) to 140oF (60oC) although some products might be stress rated for solution as check out this site high as 180oF (82oC) - custom hdpe pipe manufacturing Midland TX.

Speak with the pipe producer for info on applications. The within surface area of HDPE pipeline is without any kind of roughness which positions it in the "smooth pipeline" category, a classification that results in the least expensive resistance to liquid circulation. For water applications, HDPE pipeline's Hazen and Williams C variable for layout is 150 and does not transform with time.

The Ultimate Guide To American Plastics

Thorough conversation of this topic can be located in Phase 9 of PPI's Handbook of Polyethylene Pipe, second ed. Publications available from the pipe producer might additionally cover this topic. Yes, pipeline bursting has verified to be an extremely important means of pipe rehab. The pipeline rehabilitation sector has actually embraced "pipe bursting" as the name of the procedure of bursting fragile pipes (e.g., cast iron, clay, etc) (Texas hdpe pipe manufacturer).Prep work of the host pipe to obtain the HDPE pipe is achieved with a cone designed head in both breaking and splitting processes. Refer to PPI Handbook of Polyethylene Pipe, Second ed., Chp 16.

In-depth discussion of this topic can be located in Phase 9 of PPI's Handbook of Polyethylene Pipe, Second ed. The pipe rehabilitation market has actually taken on "pipe bursting" as the name of the process of fracturing brittle pipes (e.g., cast iron, clay, etc).

Prep work of the host pipeline to obtain the HDPE pipeline is accomplished with a cone designed head in both bursting and splitting processes. Refer to PPI Handbook of Polyethylene Pipe, 2nd ed., Chp 16.

HDPE pipelines are field evaluated and proven to be influence hard. Hydrocarbons do not deteriorate polyethylene but can diffuse via the wall of HDPE pipeline in locations of gross contamination.

Report this wiki page